A few months ago, I was working with a production manager in the Midwest. There was an urgent need to cut labor at this plant. Everyone was in agreement; the owner, the general manager, as well as my student, the production manager. After 3 days of experimenting with various ways to cut labor, the plant was spinning like a top and was truly lean and mean. At the start of the next day, it was clear to the manager that the plant could run better with fewer people. Mission accomplished, I thought, but what happened next that day was extra-ordinarily peculiar. On this last day, I gave the manager carte blanche to use everything that he’s learned and to make his own mistakes and to make the successes of the day his own. In an attempt to cut labor, the manager actually increased labor! Is it polite or politically correct to say that he made a very stupid mistake? When I think about what he did, I can hardly believe it. When I think about sharing it with you in this column, I fear that you’ll read it and either think that I am making this up or that you recognize what was done as something that you’ve done and you realize that I have, in a roundabout way, just called you stupid! I am walking on thin ice here, but I believe that if just one person benefits from this, it will be well worth this risk.

This is so important to discuss during these days of declining piece counts because cutting labor is of paramount importance. But if one attempts it and it proves futile, then you can easily become gun-shy. Then you leave your labor cost where it is and miss the opportunity to save lots of money.

The entire business world revolves around your cost per piece. Or at least your labor cost per piece. 99 out of a hundred drycleaners couldn’t tell you either one, but I am going to help you with that, not by telling you what your cost is (only you can do that), but by showing you how to tell when it goes up and when it goes down. That’s almost better than knowing your actual cost.

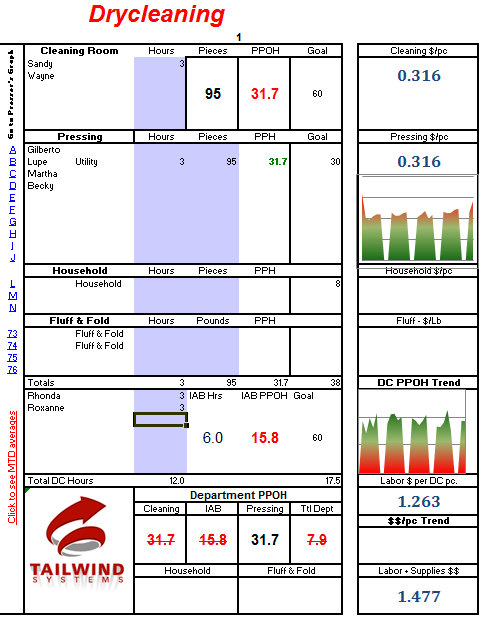

Forget about how much you pay somebody. Forget about how much you pay a particular person. Come up with a math formula called Pieces Per Labor Hour (PPLH). You’ve probably heard me talk about this before. The way to cut labor at this particular plant – and this happens to be true at many plants – is to attain and retain maximum productivity and make sure that all of the non-pressing personnel finish work promptly when the pressers finish. That is how we cut labor at this plant during the first 3 days. We had 3 pressers pressing a total of 95 pieces per hour. In addition, we had a drycleaner/spotter and two people in the inspection arena to do assembly and bagging. That is a total of 6 employees in order to produce – start to finish – 95 pieces of drycleaning. This is 15.8 PPLH. Very respectable. So, what did the manager do? He saw that there were only about 100 pieces left to press so he sent two of the pressers home. This evidently sounded like substantial labor savings to him because there were two less people to pay. The fact is, the labor cost went up, and it went up HUGE!! Would you believe, doubled? It took the remaining presser 3 hours to press 100 pieces. The drycleaner hung around to do post-spotting, and (believe it or not) 2 people remained in the inspection/assembly area. The presser was only pressing 33 pieces per hour and there were 4 people on staff! PPLH: 8.25. In case you’re interested (or haven’t fainted yet) the cost per piece for labor (assuming an average hourly rate of $10) sky-rocketed to $1.20 from $.60. It’s no wonder that drycleaners are guy-shy and skeptical about cutting labor. Perhaps they have tried it in the past and it didn’t work out in their favor?

As I was in the process of writing this column, I shared this story with another client. I told him what this manager did. When I said, “He thought that he cut labor because there were 2 less people to pay”, I got a very interesting reaction. He believed that there was labor savings here too. He was, in fact, stunned at the point that I was making and simply dying to get an explanation. It’s really quite simple, but it seems to be a revelation to some people, maybe many.

As I was in the process of writing this column, I shared this story with another client. I told him what this manager did. When I said, “He thought that he cut labor because there were 2 less people to pay”, I got a very interesting reaction. He believed that there was labor savings here too. He was, in fact, stunned at the point that I was making and simply dying to get an explanation. It’s really quite simple, but it seems to be a revelation to some people, maybe many.

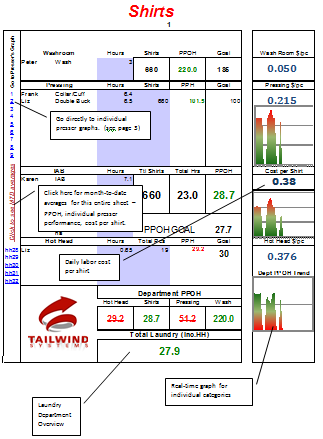

The picture at left is a page from a PPLH monitoring spreadsheet that I custom-design for Tailwind System clients.

This is the only way to learn how to monitor labor to make sure that you don’t accidentally increase labor while, at the same exact time, fully believing that you are cutting labor. The importance of understanding this is most important. It can save your life and save your business. I cannot stress this enough. The next two graphics display the example that I described earlier. Remember the manager that sent 2 pressers home because there wasn’t that much work?

You know what I tell you, month after month….

“If you do what you always did, you’ll get what you always got!”

Donald Desrosiers

Don Desrosiers has been in the laundry and drycleaning industry for over 30 years. As a management consultant, work-flow systems engineer and efficiency expert, he has created the highly acclaimed Tailwind Shirt System, the Tailwind System for Drycleaning and Firestorm for Restoration. He owns and operates Tailwind Systems, a management consulting and work-flow engineering firm. Desrosiers is a monthly columnist for The National Clothesline, Korean Cleaners Monthly, The Golomb Group Newsletter and Australia's The National Drycleaner and Launderer. He is the 2001 winner of IFI's Commitment to Professionalism Award. He has a website at www.tailwindsystems.com and can be reached at tailwindsystems@charter.net or my telephone at 508.965.3163