So, you’re heading to the Clean Show in a couple of months and if you read my column, surely, you’re on a mission. Let’s consider this month, the true cost of use; the real cost of ownership of something. This can be a challenge, no matter the product or service that you’re trying to compare or understand.

There are certain everyday products that we can use as examples. They are not perfect metaphors for what I want to share with you today, but they are likely to open your mind and get you thinking. If Shick or Gillette offer you a “free” razor, it is not hard to figure out their true agenda. Once you own this razor, you will need to buy these blades which costs way too much money. If they want to sell you their razor blades, they can manufacture a customer by giving them a free gift. The true cost of that “free” razor is probably very high. In fact, it surely is.

What about color ink jet printers? They are very inexpensive to buy, but the combined cost of the replacement ink cartridges is often close to, if not more than the cost to buy the printer in the first place! Really? I had a color laser printer in my office that cost about $1100 several years ago. The replacement toners, collectively cost $775. I hated that so much. When it can time to replace the printer, it only cost a few hundred dollars to buy it and my staff was pretty smart. They looked into the cost of the replacement toners. It’s only $250. We all felt smart. Lower up front cost. Lower maintenance cost. Lower cost per piece… I mean page. Or is it? Now, with my new printer, it seems like there is always at least one toner that needs replacing. Geez. I wish that I had figured my “cost per page” when I had the more expensive printer/toner, because, if I had, I would be able to compare the costs with what I experience today. The toner cartridges are one third the price, but what good is that if they print one quarter the number of pages? And its probably fewer pages than that!

So, you likely see my point. What is the true cost of ownership of anything that you buy? It is hard to pinpoint costs for an example that illustrates this, so I will generalize certain costs to make my point clear. Consider this:

You are considering two different shirt units. One costs $40,000 and another one costs $25,000. Let’s give them generic brand names; 40k and 25k.

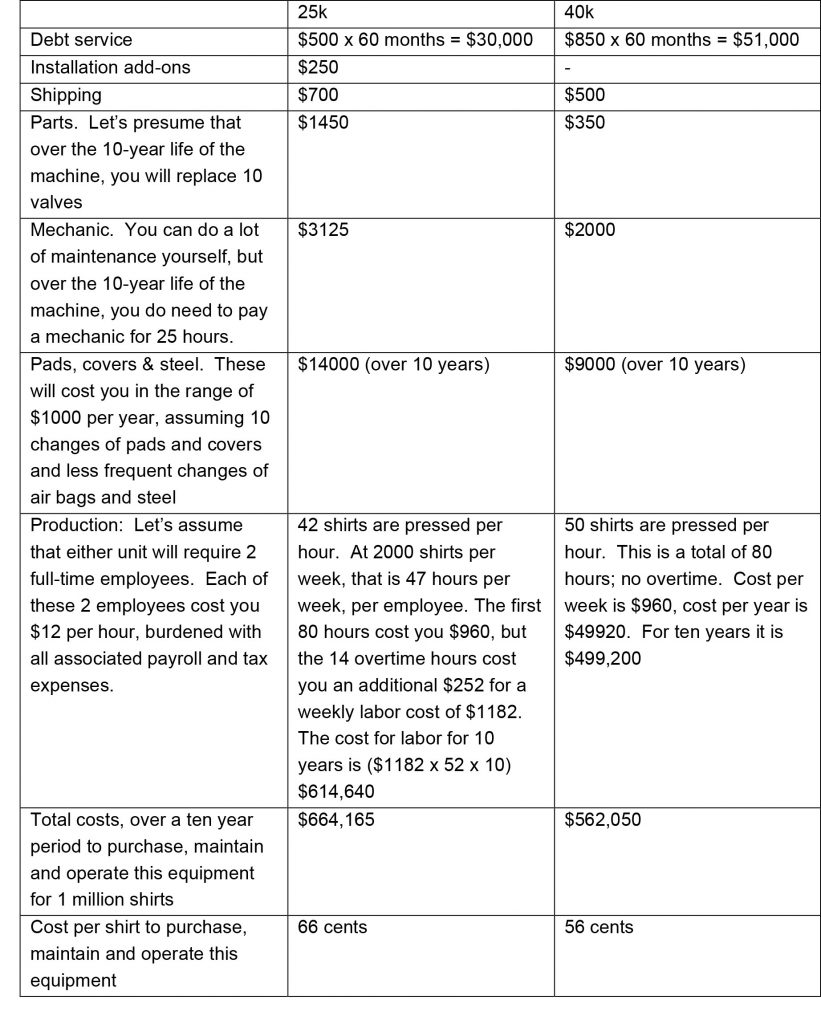

You are not full of money so the 25k is looking really good. You can finance this for $500 per month and have a brand new unit. If you opt for 40k, it will cost $850. In both cases, it’s a 60-month deal. Hmmm. $75+ more per week. Still a single buck unit, one operator. If you want to save money, the way to go seems obvious. You process 2,000 shirts per week.

Now you do some research and learn a whole bunch of things:

- 40k will ship to your plant for $500. 25k will ship to your plant for $700

- The typical pneumatic valve on 25k is proprietary to the equipment manufacturer and cost $145 each. A similar part on 40k is in the Grainger catalog for $35.

- 40k shirt unit comes with all the steam traps included. Plug and play, so to speak. Not so with 25k. You’ll need to purchase 5 traps at $50 each.

- Pads and covers (let’s assume that they will last 10,000 shirts on each unit). For unit 40k, it costs $900 to replace all the pads, covers and steel. For 25k it costs $1700. This is the cost for a year’s worth of pad & cover maintenance. And speaking of maintenance, the local distributor has a staff of maintenance people for 40k and he charges $80/hour. 25k has fewer reps and supply and demand has pushed their rate to $125/hour.

- Now let’s look at productivity. 40k can do 50 shirts per hour, but you fail to find anybody that can do more than 42 using 25k.

- Let’s presume that the units will last for 10 years and you will pay on them for 5 years, and you will do 1,000,000 shirts on them.

I will ignore the cost of training employees, but you probably should not. I will ignore the utility consumption, but you should not. I will not address the possibility that you will need to buy a bigger boiler or a new compressor for one unit, but not the other. You should definitely not ignore this either.

So, let’s do some math.

Ten cents more per shirt. Forever. Now consider this: All other factors remaining constant as described here, if shirt unit 40k cost $140,000 it would still be less costly to own and operate than the unit costing $25,000!

These are indeed hypothetical numbers, but they are based in reality. The lesson to be learned is simple. The price tag on the equipment that you covet at the Clean Show represents a very small portion of the true cost of operation. Do your homework!

“If you do what you’ve always done, you’ll get what you always got.”

Donald Desrosiers

Don Desrosiers has been in the laundry and drycleaning industry for over 30 years. As a management consultant, work-flow systems engineer and efficiency expert, he has created the highly acclaimed Tailwind Shirt System, the Tailwind System for Drycleaning and Firestorm for Restoration. He owns and operates Tailwind Systems, a management consulting and work-flow engineering firm. Desrosiers is a monthly columnist for The National Clothesline, Korean Cleaners Monthly, The Golomb Group Newsletter and Australia's The National Drycleaner and Launderer. He is the 2001 winner of IFI's Commitment to Professionalism Award. He has a website at www.tailwindsystems.com and can be reached at tailwindsystems@charter.net or my telephone at 508.965.3163