Replacing your boiler sight glass

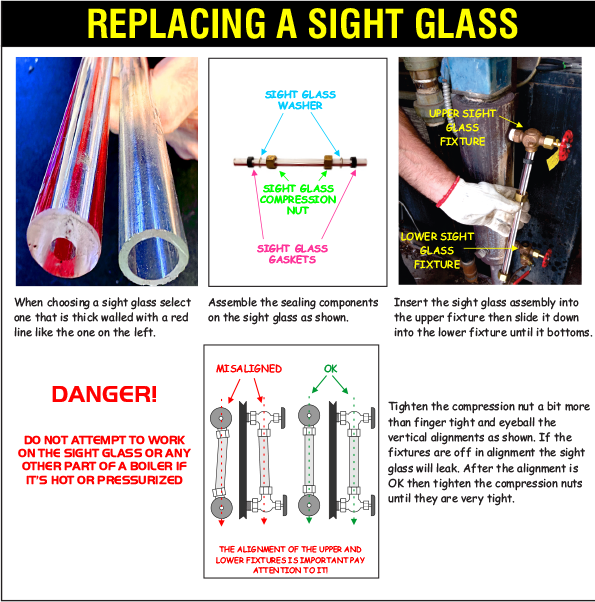

One of the most common repairs required on boilers is the replacement of the water column sight glass. This is an easy repair that MUST BE DONE WITH THE BOILER COLD. When changing the sight glass, be sure to use new parts and a length of glass that exactly matches the specifications for the water […]

Replacing your boiler sight glass Read More »