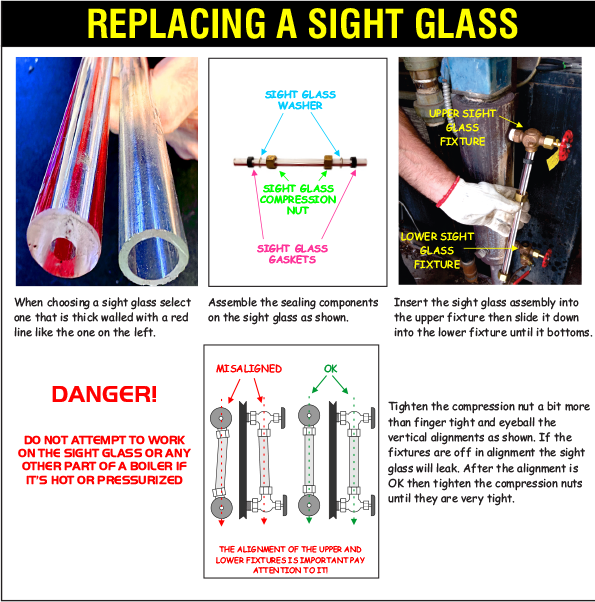

One of the most common repairs required on boilers is the replacement of the water column sight glass. This is an easy repair that MUST BE DONE WITH THE BOILER COLD. When changing the sight glass, be sure to use new parts and a length of glass that exactly matches the specifications for the water column on your boiler. I recommend a heavy-walled, red-striped Borosilicate 3.3 Industrial Grade glass as pictured in the accompanying illustration. Not only is this type of heavy-walled glass safer, but it will also significantly outlast the thinner-walled types. You will require 2 gaskets, 2 washers, and 2 compression nuts.

Here’s the procedure to replace the sight glass:

- The night before the scheduled repair, blow the boiler down completely. Always wear gloves as well as face and eye protection when repairing anything on a boiler. The following day, be sure the blow-down valves are open and there is no pressure in the boiler. Then spray the compression nuts and the upper and lower sight glass fixture valves generously with Blaster or Liquid Wrench penetrant. Allow 15 to 20 minutes for the penetrant to work.

- Remove any protective rods surrounding the sight glass, then unscrew the sight glass compression nuts and slide them towards the center of the sight glass. When the compression nuts are clear of the fixtures, push the sight glass upward until the lower end of the sight glass clears the lower fixture, tilt the sight glass outward, and slide it down; when it clears the upper fixture, remove it.

- Examine the upper and lower sight glass fixtures and be sure old gaskets aren’t stuck to them. Clean any scale or debris from the threads on the fixtures. Check to be sure there aren’t any glass chips or debris in the lower sight glass fixture.

- Assemble the sight glass components as shown in the illustration. Tilt the sight glass and slide the assembled sight glass into the upper fixture. Then align the sight glass over the hole in the lower fixture and allow it to slide down until it stops. Provided the sight glass is the proper length, there will be enough area on both ends to allow the sight glass gaskets to seal properly.

- Tighten the sight glass compression nuts a bit more than finger-tight and visually check the alignment of the fixtures relative to the sight glass, as shown in the accompanying illustration. If the fixtures are more than slightly off, the sight glass may leak.

- If you are installing a red line sight glass, be sure to rotate the glass so the level will be visible to an observer. Position the glass, and while holding it, alternately tighten first the top and then the bottom compression nut. It’s difficult to describe how tight to torque them down, but almost very tight is my best explanation. Although we don’t recommend it, they can easily be tightened further after the boiler has a head of steam (see STEP 7). Otherwise, further tighten the compression nuts when no boiler pressure is present.

- Turn on the boiler. When it comes up to pressure, check for leaks. If there are leaks, cautiously tighten the compression nut about 1/4 turn at a time until the leak stops. THIS MUST BE DONE CAUTIOUSLY WHILE WEARING GLOVES AS WELL AS FACE AND EYE PROTECTION. BE SURE YOU HAVE A CLEAR EXIT PATH FROM THE BOILER ROOM). When satisfied, replace the guard rods.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.

1 thought on “Replacing your boiler sight glass”

Nice job Bruce thanks for supporting the industry

Comments are closed.