My last assignment was a lesson for both my client and myself. This was a classic example of a very intelligent person positioning plant equipment without the benefit of knowledge of basic industrial engineering as applicable to the drycleaning and laundry industry. The challenge of a better work flow was then laid upon me since the main problem was how to produce the work faster and with good quality.

PROPER PIPE SIZE, TRAPPING AND INSTALLATION

This is the first step to good production. If the pipe size is too small, the steam pressure in the beginning will be considerably higher than the steam pressure at the end; and if the pipe run is too long, the steam will begin to condense way before the end even though the end is trapped. In this case, the run should have been trapped every 30 feet in addition to the end trap; and it was not trapped in that manner. Laundry presses at the end were not as hot as those in the beginning of the steam header run.

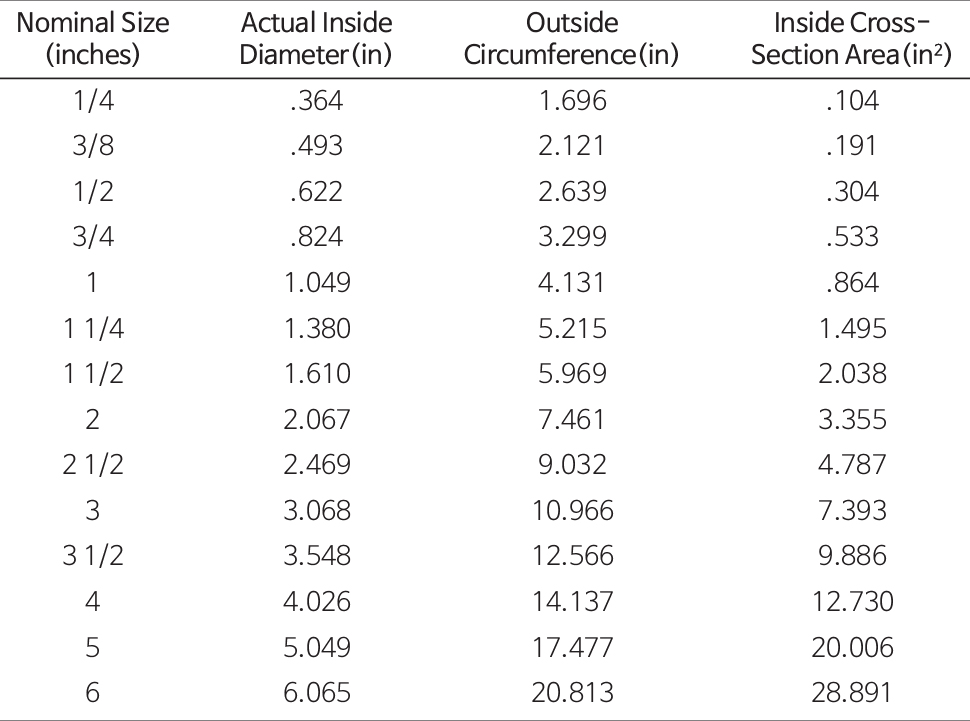

The size of the steam and condensate return header must be computed according to the scale as set forth in ASME specifications.

Most plants install their headers perfectly level. This is a grave mistake since a steam header will serve as a pocket of water after the boiler has been turned off for a few hours. This results in rapping, knocking and lost time to reach operating pressure during boiler start-up in the morning. In addition is harmful to the joints and fittings and causes leaks, etc. The proper installation is to pitch the steam header from the boiler down one inch per ten feet of run with a properly sized trap every 30 feet and a properly sized trap at the end with a drain leg at the end. The condensate return header should then pitch down toward the boiler room’s condensate return tank the same one inch per ten feet of run. Both headers should be strapped and supported every ten feet, and insulated to prevent heat radiation. By pitching down toward the boiler room’s condensate return tank, the water of condensed steam will easily flow, by gravity, from the steam header, through the header trap and down through the condensate return header into the condensate return tank.

This plant did not conform to the above specifications, and, therefore, production of laundry pressing was considerably restricted at the end of the steam header run. Also, sub-headers for small groups of laundry presses were too small in diameter to maintain the required heat for pressing production. Although, I cannot blame the current plant owner for all the misgivings since this plant was originally installed by another owner quite a number years ago, subsequent equipment installations were made without thought to proper engineering principles as noted in this article. Also, the plant was well ventilated and kept clean throughout.

PROPER STEAM PRESSURE FOR LAUNDRY AND DRY-CLEANING

First, we have to begin with the steam pressure rating of your boiler. An ideal selection is a boiler rated at 150 pounds per square inch (psi) maximum steam pressure. A maximum steam pressure rating of 125 psi is the minimum acceptable. Pounds per square inch is usually written as psig (pounds per square inch gauge) since that is where the measurement is always taken.

For maximum laundry production a working steam pressure of 115 psig to 120 psig is ideal. A minimum acceptable working pressure is 110 psig. These numbers are at the boiler, but will have little drop at the units as long as the pipe, installation and traps are correct as noted herein. This plant’s boiler had a working pressure of an average of 90 psig to 95 psig, although occasionally the steam pressure climbed to 100 psig. This was corrected by the owner’s adjustment of the pressuretrol, and replacement of a couple bad traps.

By the way, the best rated bucket steam trap is 80 psi, not 125 psi, since the former has a larger orifice opening and will discharge the condensate quicker than the 125 psi trap resulting in a hotter press head and buck for better production of laundry.

The drycleaning department requires a steam pressure of 65 psig to 70 psig since the steam pressure over 70 psig is too dry for removing wrinkles and spots quickly. The steam pressure was set by pressure regulator at 80 psig resulting in lost pressing time.

PROPER LAYOUT OF CLEANING AND FINISHING UNITS

Too much time was spent in walking rather than working. In the drycleaning department the topper was too far from the legger, the recovery tumbler was too far from the washer-extractor and the steam-air form finisher was too far from the utility press. Neither the workers nor the supervisors ever complained, or even suggested, to the owner about the inefficient layout.

In the laundry finishing department, the layout of the shirt unit required two operators for finishing and one for touch-up, whereas the amount of equipment could have been configured easily for only one operator. The touch-up person pressed most of the shirt redundantly to justify her job and not because the shirts required it.

The layout of the pants units required as much as four to five pressers to do the work of only two single operator units turning out a little more than the two multiple operator units (after the correction of the pipe, steam pressure, etc., as explained above).

In the laundry finishing units, a saving in production labor as well as increased production will be ultimately realized. Overall, the owner will change the entire plant layout in the near future, and his assembly areas will be reduced for better “lot” control and reduced walking since both the laundry and drycleaning operations will be together in one large room instead of two large rooms. Even the marking tags and system will be changed for more efficiency and customer satisfaction.

EQUIPMENT IN GOOD WORKING ORDER

In the drycleaning department, the vacuum on one utility press was very weak due to the small size of the vacuum header and the accumulation of water in the vacuum take-off line at the ell into the press vacuum valve. This could be corrected by substituting a tee for the ell with a nipple and ball valve for draining that take-off (recommended for correction as soon as possible). The replacement of the undersized vacuum header was also recommended as soon as possible.

Two utility presses had defective head steam valves. One utility press had a defective check and leaking air cylinder. One set of puff irons was inoperative. None of the operators, including the supervisor, ever reported these defects to the owner. In addition to physical correction of these deficiencies, a maintenance management system was explained and recommended to the owner. Supervisors are now required to test all presses each morning for defects in addition to an effective preventive maintenance operation.

Fortunately, in the laundry department most of the equipment was in good working order, but the preventive maintenance procedures as prescribed are now in effect.

PROPER AMOUNT OF WATER RETENTION IN LAUNDRY FOR FASTER FINISHING

Too much water retention after extraction resulted in extended drying times under the press heads, especially for pants and heavy shirts. This was corrected by extending the extraction time to no more than two thin streams of water at the end of the extraction cycle.

LACK OF PROPER INSPECTION FOR SPOTS AFTER CLEANING

In the drycleaning department the spotter/supervisor neglected to carefully inspect garments for spots before distributing them to the pressers. The pressers were required to look for spots which consumed too much time resulting in poor production. I recommended utilizing an inspection table with excellent fluorescent daylight tubes for the spotter to examine each garment for spots before distribution to the pressers. Unremovable spots, or possible damage to the fabric and dye, were noted by use of a “sorry tag” attached to the garment by the spotter before distribution to the pressers. Supervisors are charged with ensuring valid use of the tags rather than a substitute for spot removal or attempt to remove if damage is suspected. Pressers, inspectors, CSR’s and customers are alerted by the tag instead of re-processing to avoid duplication of effort and loss of production time.

PREPARATION OF SHIRTS AND PANTS FOR LAUNDRY PROCESSING

Shirts had button-down collars and both cuffs buttoned when processed causing the wash person and pressers to lose time unbuttoning the shirts. To correct this situation, the markers were instructed to unbutton collars and cuffs and to button all pockets. Supervisors were charged with ensuring these requirements

As revealed in this article, there are many detriments to good production in the pressing department that are not obvious nor expected.