With summer upon us, your dry cleaning machine’s cooling system will be under greater stress. It doesn’t matter if you are using a water tower, chiller, or city water for cooling; conditions that weren’t an issue during the cooler months may become problems as the ambient (surrounding) temperature rises. Most of the cooling problems will rear their ugly heads during the drying segment of the dry cleaning cycle. Drying, in the dry cleaning machine sense, is all about moving heat energy. The media which moves all this heat is called a refrigerant (most machines use R22 Freon. Some of the newer models and the K4 machines use R400 Freon as refrigerants) and some form of coolant (generally water or a water and glycol mixture).

It doesn’t matter which Freon is used; the process itself requires a device called a REFRIGERATION CONDENSER which changes hot, vapor-rich Freon gas back into liquid Freon, which is constantly being recycled during the drying segment of the dry cleaning cycle. In almost every case, this condenser is cooled by a liquid (there are a few air-cooled condensers that are not this article’s topic).

Hot, compressed Freon gas is forced by the REFRIGERATION COMPRESSOR into the REFRIGERATION CONDENSER, where it is cooled and condensed by water (called a COOLANT). In this case, we are transferring the heat from a vapor-rich, hot, compressed Freon gas to the coolant flowing through the refrigeration condenser.

THREE METHODS OF SUPPLYING COOLANT TO THE REFRIGERATED CONDENSER

1. CITY WATER- water from the city main is forced through the dry cleaning machine’s refrigeration condenser propelled by existing city water pressure. The exiting water is then sent down the drain.

2. WATER TOWER– a pump circulates water through the dry cleaning machines refrigeration condenser; over an evaporative cooling media (looks like corrugated plastic tubes), which has air forced through, aiding in evaporation, into a sump where the suction inlet of the pump is connected. The evaporation of the water from the surface of the media cools the remaining water, which drops into the sump for recirculation through the dry cleaning machine’s refrigeration condenser.

3. CHILLER- water or a mixture of water and glycol (this mixture is called a brine) is circulated by a pump through the dry cleaning machines refrigeration condenser, cooled by a separate refrigeration system, and re-circulated through the dry cleaning machines refrigeration condenser.

No matter what method is used for cooling and circulating the coolant through the refrigeration condenser, the efficiency of the process is dependent on two factors:

A. COOLANT FLOW– the amount of coolant moving through the condenser.

B. HEAT TRANSFER EFFICIENCY- the ability of the condenser to move heat to the coolant.

Each of the above factors can be easily monitored using pressure and temperature as indicators of what is going on in the coolant system. A pressure gauge and thermometer at the inlet and outlet of the coolant system located near the dry cleaning machine are vital for monitoring the cooling system performance. The pump must supply enough pressure and flow in sufficient quantity to push coolant through the components that require cooling on the dry cleaning machine. On most machines, this would include not only the refrigeration condenser but also the still condenser and solvent cooler); in the case of water towers and chillers, also back to the tower or chiller sump, which are often located on the roof. Unfortunately, there is no hard fast rule for what the pressure readings should be. The best method for obtaining the “numbers” is to note the dry cleaning machine inlet, outlet pressure, and temperature readings when the dry cleaning machine works properly for future reference. Let’s have a look at what the thermometers and pressure gauges can tell us about the condition of the coolant system.

The following are some possible scenarios for different combinations of qualitative data:

1. Inlet pressure high/outlet pressure low:

A. Check for blockage inlet flow path- a clogged Y strainer between the pump and the dry cleaning machine:

B. Heavy scale build-up- the build-up of scale inside the piping of the dry cleaning machine.

2. Inlet and outlet pressure rapidly changing:

A. Low coolant level in the pumping system.

3. Low inlet/high outlet pressure

A. Open bypass valve on pumping system:

4. Low inlet/low outlet pressure

A. Pump off

B. Clogged inlet strainer

5. High inlet temperature/high outlet temperature:

A. Water tower fan not working/chiller refrigeration system faulty.

B. Pump off

6. Slightly higher than normal inlet temperature/high outlet temperature:

A. Heavy scale build up- a build-up of scale inside the piping of the dry cleaning machine.

B. Excessive heat source- still boil over or steam sweep valve open; steam supply valve to steam boost coil or carbon adsorber.

Back to the dry cleaning machine operation- Problems with the cooling system will most likely appear during the dry cycle. To be more specific, towards the end of the dry cycle when the dry cleaning machine goes into cool down mode. During the drying mode, the heat exchanger coil transfers much of the heat from the Freon to the air stream, and only a small portion of the heat load is being dumped into the refrigeration condenser. In the cool-down mode, solenoids and dampers change, and almost the entire heat load is now dumped into the refrigeration condenser. This type of problem is indicated by the REFRIGERATION COMPRESSOR entering a high-pressure condition and tripping the REFRIGERATION HIGH-PRESSURE SAFETY SWITCH. This would usually cause an error message on the programmer screen and require a manual rest of the refrigeration high-pressure safety switch. This condition is almost always caused by either a clogged Y strainer or excessive scaling inside the refrigeration condenser. Most dry cleaning machines have a REFRIGERATION HEAD PRESSURE ADJUSTING VALVE, which controls the refrigeration head pressure by varying coolant flow to the refrigeration condenser. This valve is adjusted to give sufficient refrigeration head pressure for efficient refrigeration system operation. When scale builds up in the refrigeration condenser past the point where the normal adjustment of the head pressure adjusting valve can compensate, many dry cleaners simply open the valve wider in the VERY MISTAKEN belief they have fixed something. What they have done is “kicked the can down the road” and will pay a lot of extra money in solvent and energy for the privilege.

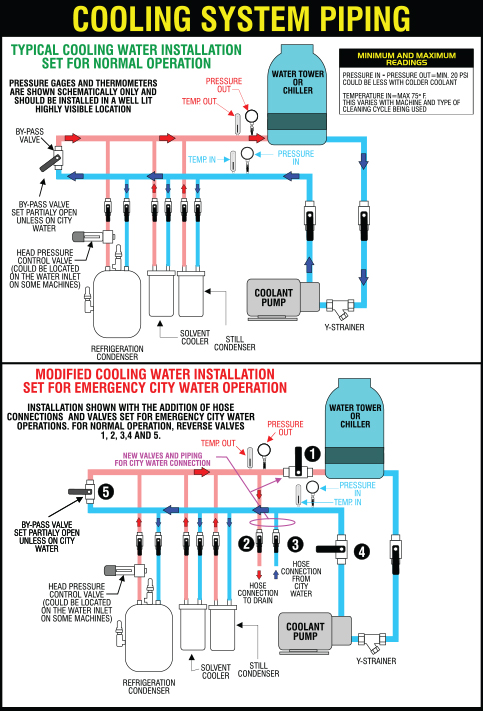

The accompanying illustrations show schematics for typical cooling water installations on systems using a water tower or chiller. The top illustration is most commonly found; the bottom is an installation WITH THE ADDITION OF VALVES 1,2,3, which are used when city water hook-up is included in the installation. This city water hook-up provides an emergency back-up for continuing operations when there is a failure in the normal cooling system and ready access for connecting a descaling pump.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.