Mr. JG Cho even started a wholesale service thanks to AquaMax Wetcleaning System

Paradigm Shift. It is a fundamental change in the underlying assumptions, beliefs, or methods within a particular field. Like when Copernicus proposed that the Earth revolves around the Sun, not the other way around. Mr. Janggeun Cho who operates Kimber Cleaners in South Amboy, NJ, has been wetcleaning for the last 10 years. But he says his knowledge and experience about wetcleaning was completely upended. Let’s find out what happened.

It took him 10 years to open his own store

Mr. Cho came to America in 2006. And like so many who came before him, he found a job at a dry cleaner through a local church.

“This store was using hydrocarbon solvent. I started as a shirt presser. Of course, I ended up learning everything about running a drycleaner after 10 years.”

The couple managed to get their own store after 10 years of savings. It was called Hidden Lake Cleaners in Hidden Lake, NJ. The previous owner was moving out of the state and the Cho’s took over the store as a bargain. But there was one problem.

“The store had a wetcleaning machine called AquaSolo and no drycleaning. The previous owner switched from perc to wetcleaning. It was the first time I heard of AquaSolo and wetcleaning.”

Mr. Cho had plenty of experience working with water. And he and his wife were utterly repulsed by the solvent smell. So, in a way, they were glad that the store had no solvent smell.

“The previous owner sent out suites and only washed washable clothes in house. But I couldn’t do that. It was not an option for me. So, I had to learn wetcleaning by myself. I even joined a wetcleaners’ group.”

Fortunately, the AquaSolo machine had a 100% manual mode so Mr. Cho ran the machine as if he was handwashing. And he hung dried everything. Working in that fashion, he ended up working until 9 PM even though the volume was modest.

“It was only bearable because my house was only 5 minutes away. On top of that, customers began saying compliments about our cleaning quality. They were also happy there was no chemical smell in the store. The difference was mostly noticed by women.”

After 4 years of working like that, his crazy routine started to feel “normal.” Then, the AquaSolo machine broke down and had to be replaced. It was a perfect opportunity to get a drycleaning machine but he ended up getting a Wascomat. He had no choice because his customers hated the chemical smell as much as the couple.

“Sometimes, I sent out some items to a friend’s drycleaner. Then, the customer knew it right away. When there was a drycleaned cloth among wetcleaned clothes, it was immediately detected.”

So, Mr. Cho maintained his crazy daily routine for 8 years. Going home at 9 PM everyday.

Moved into Kimber Cleaners last January

His business went down during the Pandemic and the local demographics shifted as well. The lease ended last January so he moved his business to the current Kimber Cleaners in South Amboy, NJ. And there was a drycleaning machine in this plant.

“I probably rand 3 or so loads and but I and my wife were repulsed by the smell. So, we bought a used Wascomat.”

The problem was that one 55 lbs. Wascomat washer was not big enough to handle the increased volume. Working until 9 PM now seemed like good old days.

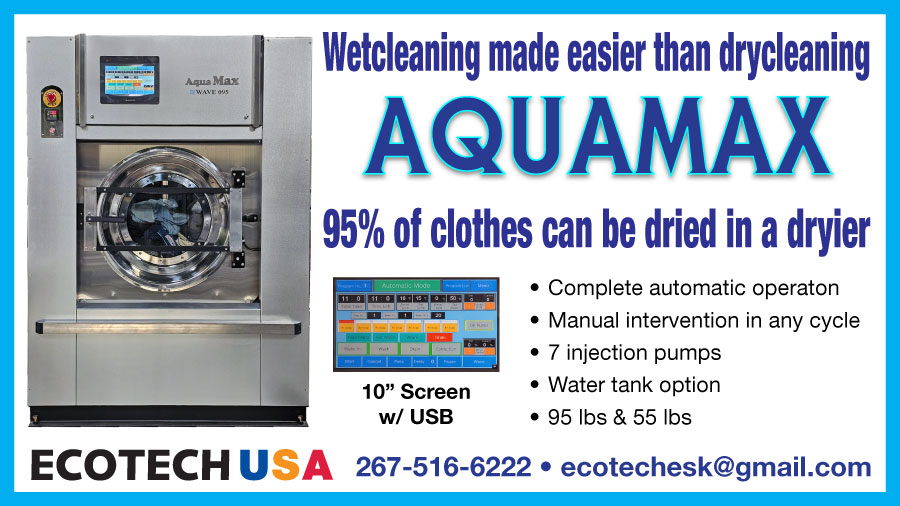

Then, he saw an ad about AquaMax Wetcleaning System.

“I have been running my machine manually so I wanted a machine that can execute my procedure. They said they can. They even told me they can dry most of wetcleaned clothes in the dryer. I didn’t know what to believe.”

The AquaMax Wetcleaning System went on sale in February and a cleaner in Red Bank, NJ purchased it. So, Mr. Cho wasted no time to visit the store to see for himself.

“I went there as soon as I heard. The clothes coming out of the dryer felt as if they were drycleaned. The owner was already making his own programs. I already had a large dryer. It was a no brainer.”

AquaMax Wetcleaning System was installed in Mr. Cho’s store in March. He took out the German drycleaning machine and installed AquaMax in its place.

Go home at 6 PM sharp

The one thing Mr. Cho was dying to do was to dry wetcleaned clothes in the dryer. Hang drying everything was such a burden but he was too afraid to try any other way.

“I was nervous when I ran the very first load in my new machine. But as soon as I grabbed the washed clothes, I felt the difference. I knew immediately that I will work.”

Mr. Cho says even though washed clothes must be transferred to the dryer, he is saving at least 20 minutes every load compared to drycleaning. His time at the spotting board was halved at least.

For the last 10 years of wetcleaning, production speed was the unavoidable bottleneck. But now, the production finishes before 3 PM. Even with the increased volume.

“My work got at least 70% easier with the new system. Pressing got easier by at least 80%. Dried clothes have almost no wrinkles so my pressers say ‘NO PROBLEM.’”

“Before AquaMax, I had to pore through every piece with the utmost care. No more. The most attention I give now is shaking off clothes before I put them in the cart.”

Now, Mr. Cho goes home at 6 PM sharp. He was never able to do that for the last 10 years of wetcleaning.

There is another impossibility that he does now.

“I have so much time on my hand now I started to do some wholesale work. I never ever dreamed of doing the wholesale work with wetcleaning. It’s an absolute 10 out of 10. Ha ha.”

If you have any questions, please contact him at (732) 213-7243.