In this issue, I’ll be finishing the series on gaskets and adhesives with two more useful families of products. CYANOACRYLATES, much more difficult to pronounce than use, and SILICONES which are amazingly versatile gasketing material.

Starting with CYANOACRYLATES, popularly known as Super Glue and Crazy glue have some unique qualities. It will bond to almost anything and will even bond to most moist surfaces including skin and flesh (some types of cyanoacrylates are used in surgical procedures instead of sutures or staples) so be careful about getting any on yourself. There are 2 types. One has a thin watery quality the other a thicker gel-like consistency. I find the thin water-like type useful for repairing cracks in almost anything plastic. It “wicks” (flows) into cracks and fractures in plastics and will actually fuse narrow cracks or fractures in pvc, abs, polycarbonates, and many other families of plastic (do not use on cotton or leather). The idea is to apply a small amount of glue allowing it to flow into the crack or fracture then apply pressure pushing the crack or fracture closed. Generally, a few minutes is time enough to allow the glue to be adsorbed and cure. To me, the most outstanding quality of cyanoacrylate is its ability to bond most rubbers. This is especially helpful in making or repairing O-Rings (see the accompanying illustration) and gaskets. The bonded joint is usually stronger than the rubber itself.

Starting with CYANOACRYLATES, popularly known as Super Glue and Crazy glue have some unique qualities. It will bond to almost anything and will even bond to most moist surfaces including skin and flesh (some types of cyanoacrylates are used in surgical procedures instead of sutures or staples) so be careful about getting any on yourself. There are 2 types. One has a thin watery quality the other a thicker gel-like consistency. I find the thin water-like type useful for repairing cracks in almost anything plastic. It “wicks” (flows) into cracks and fractures in plastics and will actually fuse narrow cracks or fractures in pvc, abs, polycarbonates, and many other families of plastic (do not use on cotton or leather). The idea is to apply a small amount of glue allowing it to flow into the crack or fracture then apply pressure pushing the crack or fracture closed. Generally, a few minutes is time enough to allow the glue to be adsorbed and cure. To me, the most outstanding quality of cyanoacrylate is its ability to bond most rubbers. This is especially helpful in making or repairing O-Rings (see the accompanying illustration) and gaskets. The bonded joint is usually stronger than the rubber itself.

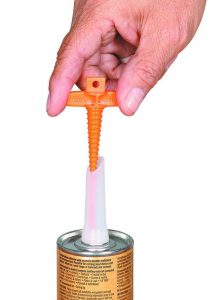

Next on the list is SILICONE sealants. Silicone comes in many different types and qualities. I prefer a brand name industrial-grade like Permetex or Loctite; use the red-colored high-temperature type. It is easy to see where you have applied it and it won’t degrade at the temperatures encountered in the dry cleaning/laundry environment. You can’t beat it for gasket forming between flat surfaces and sometimes it can even replace preformed gaskets. Silicone sealant is useful to waterproof and insulate electrical connections and since it stays flexible it’s not overly affected by motion or vibration. Have a look at the accompanying illustration for a couple of applications you may not have thought of. The only downside is sealing the tube or cartridge once it’s opened. I found a nifty device at Harbor Freight for this purpose. It’s a tapered plastic screw sort of like a tapered corkscrew that screws down into the opened tube of sealant. The Harbor Freight part number is Caulk Saver – Item#97561.

Next on the list is SILICONE sealants. Silicone comes in many different types and qualities. I prefer a brand name industrial-grade like Permetex or Loctite; use the red-colored high-temperature type. It is easy to see where you have applied it and it won’t degrade at the temperatures encountered in the dry cleaning/laundry environment. You can’t beat it for gasket forming between flat surfaces and sometimes it can even replace preformed gaskets. Silicone sealant is useful to waterproof and insulate electrical connections and since it stays flexible it’s not overly affected by motion or vibration. Have a look at the accompanying illustration for a couple of applications you may not have thought of. The only downside is sealing the tube or cartridge once it’s opened. I found a nifty device at Harbor Freight for this purpose. It’s a tapered plastic screw sort of like a tapered corkscrew that screws down into the opened tube of sealant. The Harbor Freight part number is Caulk Saver – Item#97561.

Well, that’s it for this issue. I’m looking for suggestions for subjects you find interesting to write about. Call me at 702-376-6693 or email me at bruce@eztimers.com with any requests or suggestions.

Well, that’s it for this issue. I’m looking for suggestions for subjects you find interesting to write about. Call me at 702-376-6693 or email me at bruce@eztimers.com with any requests or suggestions.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.