The Clean Show landed in Atlanta once again for the third time since 1987 and if you looked hard enough, you saw some rather amazing things. Over the next few months, I’ll share them with you, but I will tease you a bit right now. Suppose I told you that there is a new shirt unit that is a true game-changer? There is! How about a line of presses that can be raised or lowered to accommodate those particularly short pressers on your staff? Somebody has them now! Unipress made two terrific changes. One of them will make your mechanic smile from ear to ear (or whoever changes your pads and covers) and the other will make you think “Why didn’t someone think of that years ago?”

I was in Pompeii years ago. While there, I was fascinated to learn that the ancient Romans invented indoor plumbing over 2000 years ago. But when Pompeii – a city that had indoor plumbing – was wiped out in 79 A.D., the plumbing technology, which obviously didn’t spread like internet, was decimated and lost just like the city. Herculaneum, Pompeii’s much less famous neighboring city had even more people, buildings and, well, plumbing. All of it lost for 800 years before indoor plumbing was invented again. Ok, I’m kind of a history buff and my editor probably didn’t publish the beautiful picture of Herculaneum that I sent him. I told him that if listens to me and does print it, he will sell a lot more magazines! Let’s see if he listened to me.

(I have such a fun job!) I have a point here. Unipress is now offering you the option to buy a double buck shirt unit with a one buck smaller than the other, allowing you to do those smaller shirts on the shirt unit rather than require hand-finishing on the hot head. The Pompeii reference is that this idea is not new! This idea is as old as the hills! In fact, Unipress had to dig deep to find this gem. Frankly, I’m embarrassed that I didn’t think of this first. Unipress, you get no credit from me for thinking of this, but you’re a genius for bringing it back.

Back in the 1960’s my Uncle Ulric owned Star Shirt Service. He had a double-buck Ajax shirt unit. Ajax had a unique feature. The body buck was not heated (!) and had quick-disconnects for air and two Allen screws. A couple of quick motions and the buck is in your hands, seconds flat. The buck on the body press was available in a number of widths. Because of the flat heads – which was unique at the time – any width buck would work. Few people even knew about these various bucks. My uncle explained that at lunchtime when the staff went to lunch, he and his wife would swap the bucks to small ones and do the small shirts and blouses themselves. This entire thought, this entire philosophy, this entire brain wave has been lost for 60 years. Unipress was wise enough to color-code the buck too. The small buck will come covered in RED Nomex and the larger buck will come covered in WHITE Nomex. I suggest that you stick with that color scheme. My mind goes right to work with things like that. “What is a good memory aid for that?”

“Small buck = Small word!”

“Red (or Rojo) is the small buck, so this is the buck that can take a SMALL shirt and any shirt”

“White (or Blanco) larger word = larger shirts, not the small ones”

What this does, of course is the presser instantly knows what size shirt will best fit on the buck that is waiting to be dressed. And to be clear, this is a very simple thing. Both bucks take the same pads and covers. What is different is the width of the shoulders and the inner workings. As a direct result, the small buck can still do any size shirt. The large buck is 21” at the shoulders and 17” at the middle of the buck while the smaller buck has 18” shoulders and 14” midriff.

It’s been several years since Unipress introduced their tail plate. This is a passive device that automatically pulls down on the back of the shirt to yield perfect backs. They say that no good deed goes unpunished. The thorn on this rose was that changing the pad and cover on this tail plate was a bear. There were springs to break and screws to lose and new swear words to learn. Unipress will have many a pad guy smiling when they get a load of this. And best of all, you don’t need to buy a new machine to benefit. You can upgrade your old machine to this new tail plate upgrade! To see how simple it is, just click on the QR code.

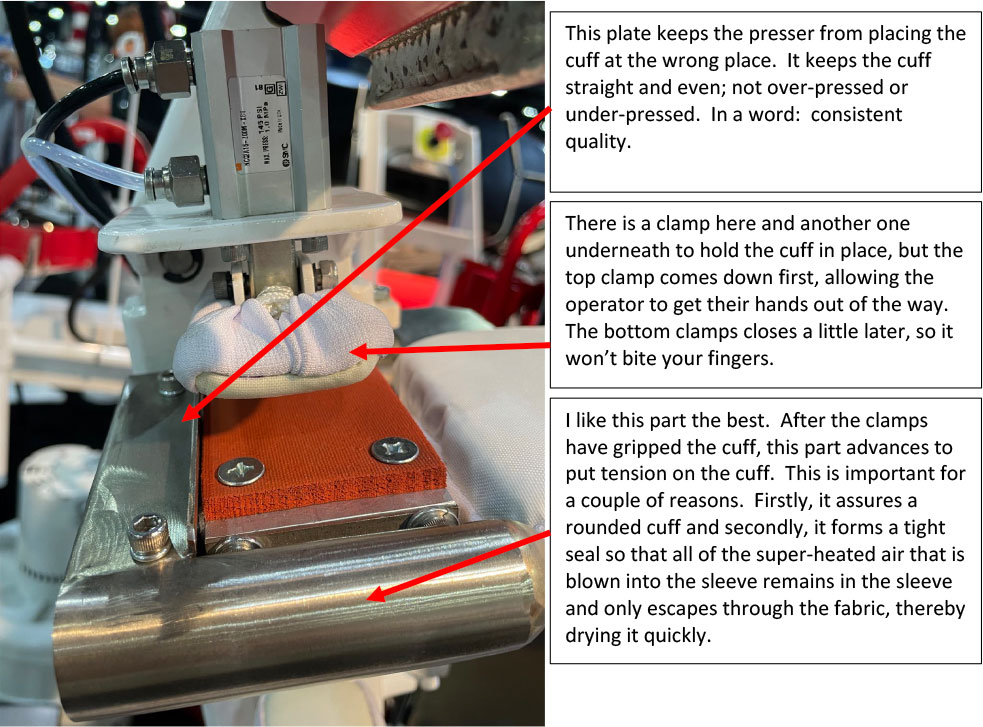

And while you’re upgrading… The new cuff clamps on the Unipress Cyclone line are something that you can buy to convert your existing machine too, but you might want to just buy the whole thing! This is one heck of a machine!

Unipress has made these cuff clamps available as an upgrade to those customers that already have equipment with older cuff clamps. This could be worth considering especially because this device assures consistently excellent sleeve pleats as well! I spent quite a while pressing on this machine in Atlanta and I also videoed Liz Davies pressing. To watch us both, point your camera onto these QR codes:

Unipress also changed the control unit on their double-buck unit. Unipress found that the features on the fancy TV screen were nice but expensive and customers did not use them, therefore they were paying for features that they did not use. Unipress elected to keep the price of their equipment down and go for a simpler design. The result is functional and excellent.

Itsumi once again demonstrated their BT550 double-buck shirt press. I always like pressing on this unique machine. Its unique half-moon shape is completely unique and is a joy to operate. They have improved the vacuum, increased the blower power by 40%, upgraded the heat chamber to be hotter thereby reducing the cycle time by 30%. Also, the sleeve angle adjustment moves more quickly and the angle is improved so that ladies blouses come out better.

To see Sammy Ahn and I pressing on this unit, click on these QR codes:

But wait! There’s more! This is only the beginning! There is still so much more to show you. Hi-Steam, Sankosha, Forenta, Pony! And I have a surprise in the coming months. I was given a private tour of an equipment manufacturing plant a little while ago and I will be sharing that with you in a few months so stay tuned!

Donald Desrosiers

Don Desrosiers has been in the laundry and drycleaning industry for over 30 years. As a management consultant, work-flow systems engineer and efficiency expert, he has created the highly acclaimed Tailwind Shirt System, the Tailwind System for Drycleaning and Firestorm for Restoration. He owns and operates Tailwind Systems, a management consulting and work-flow engineering firm. Desrosiers is a monthly columnist for The National Clothesline, Korean Cleaners Monthly, The Golomb Group Newsletter and Australia's The National Drycleaner and Launderer. He is the 2001 winner of IFI's Commitment to Professionalism Award. He has a website at www.tailwindsystems.com and can be reached at tailwindsystems@charter.net or my telephone at 508.965.3163