You’ll no doubt recall from the first article the boiler changes water from the liquid form to the gaseous state, which is steam. In the change of state, steam stores a large quantity of heat energy in the form of latent heat, which is released when the steam condenses back into water.

Now that we’ve learned how to generate steam by controlling the water level and the fire in a boiler, let’s see how delivering this steam to the machinery and returning the condensed steam, called condensate, back to the boiler is accomplished.

STEAM DELIVERY SYSTEM

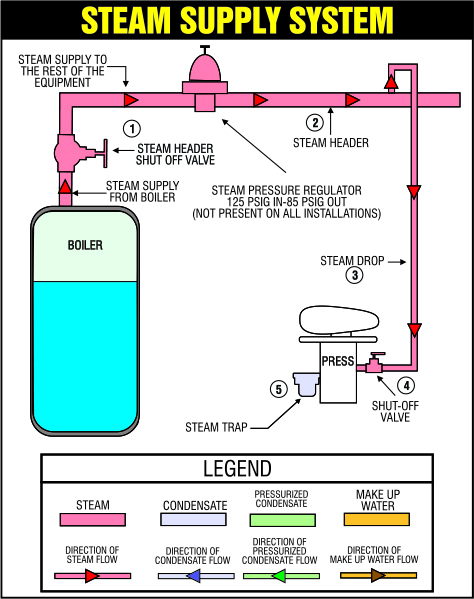

Now, let’s examine what happens to this steam in a dry cleaning/laundry operation. Steam exits the boiler through a “shut-off valve (1)” into a large main pipe called the “steam header (2).” The shut-off valve is usually a multi-turn round-handled globe-type valve, which is called the “steam header shut-off valve.” You may find it surprising that steam will step along at least a brisk 80 ft. per second minimum (55.5 miles/hour) through this header pipe. It’s a good idea to open and close this steam header shut-off valve once a month to keep it operating freely, and like all boiler maintenance, do this when the boiler is not under pressure.

Branching off the steam header are smaller “drops (3)” connecting the steam header to the steam inlet of individual machines. Each drop should have its own “shut-off valve (4) between the header and the machine.

Shut-off valves in the drops are usually of the “90 degree or ¼ turn to shut” ball valve variety.

Now that we’ve got the steam to the machine, let’s tackle the dynamics in a pressurized vessel like a press head, press buck, or heating coil. Steam is cooled by contacting the metal of the vessel (I’ll call the vessel the machine from now on), and it changes state back to liquid water (I’ll call this water condensate from now on). This change of state releases large amounts of latent heat energy. Steam contains almost all the heat energy and condensate almost none, yet they exist at the same temperature and pressure.

So, as the condensate accumulates in the pressurized vessel, steam has less space to enter and release heat energy. I’m jumping slightly ahead here, but that is the reason why when a steam trap is blocked, the machine will not heat up or just be warm.

A device called a “steam trap (5)” removes the condensate from the machine, allowing more steam to enter. Without getting into the internal workings of different types of steam traps, an “inverted bucket trap,” sort of a cylindrically shaped device, or a “thermostatic, also called thermo-dynamic trap” shaped like a small rectangular block of metal or an oversized hockey puck is almost always used in dry cleaning and laundry operations.

These devices are located at the lowest point of the machine and open when activated by the accumulation of condensate, allowing the pressure of the steam entering the machine to blow the condensate out of the machine into the piping, which returns the condensate to the boiler blown through the lines by a small amount of steam which escapes when the trap opens. The system that conveys the condensate back to the boiler is called the condensate return system and will be covered in next month’s article.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.