Last month we took the necessary components and cobbled them together into a configuration that resembles a boiler. In this installment, we’ll learn how the different components are organized into a system that maintains the proper water level inside the pressure vessel of your boiler.

To begin, keep in mind that all the controls on your boiler serve only 2 functions:

- To turn a pump on or off.

- To turn the fire on or off.

That’s it! Simple, just like a light switch toggling on or off.

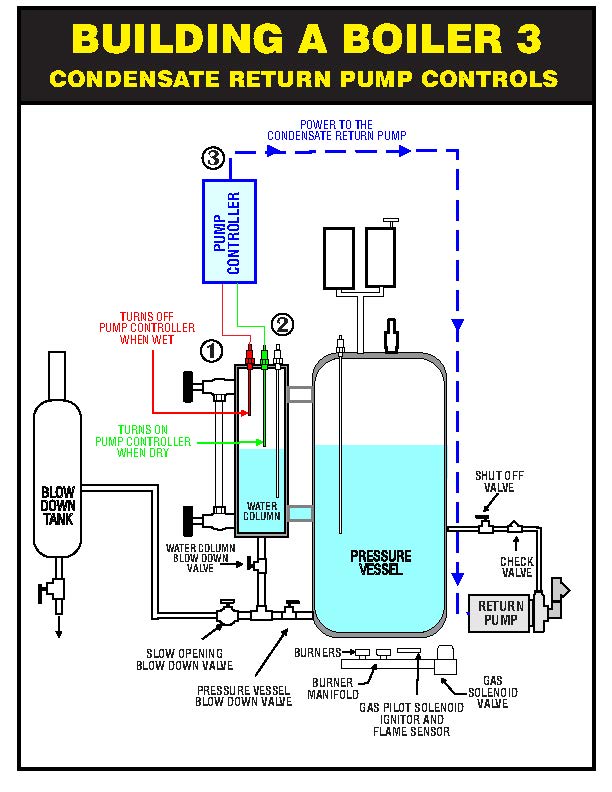

CONTROLLING THE CONDENSATE RETURN PUMP

Look at your boiler. Hanging somewhere off the side is a cylinder with a sight glass in it. This is the Water Column which provides a convenient place to monitor the water level in the Pressure Vessel. It is attached to the Pressure Vessel at 2 points; above the desired water level in the steam storage area and well below the desired water level in the water storage area of the Pressure Vessel so that the water level in the column is the same as the water level in the Pressure Vessel.

Screwed into the top of this cylinder are 3 probes that look like spark plugs. They are called Water Level probes or Water Level Sensors. These “spark plugs” have metal rods at the opposite ends called electrodes (metal rods that easily allow an electric current to pass through them), which extend down into the Water Column. When water touches the electrode, electric current passes from the rod, through the water, to the metal of the Water Column, signaling that the water is at the level of that probe. The opposite holds true when the water level drops below the rod; the current flow is interrupted, sending a signal that there is no water at the level of that probe. There are 2 probes controlling level operations (#1 Pump Off & #2 Pump On- pictured in the illustration). These probes are used to toggle the Pump Controller (3 in the illustration) on and off. When the water level drops below the electrode on the Pump- On probe (probe 2 in the illustration), it signals the Pump Controller to send power to the Condensate Return pump turning the pump on. The pump will remain on until the water level rises to contact the Pump-Off probe (probe 1 on the illustration), signaling the Pump Controller that the proper water level has been reached, thereby shutting the Condensate Return pump off.

Pretty straightforward stuff, right? Believe it or not, that’s it for controlling the pump. However, controlling the fire is another story we will explore in next month’s issue. Here are a couple of ideas to ruminate over. On almost all controls for water level, indicator lights tell you whether the probe is in contact with water. Open the boiler control panel access door (on some doors, there is an interlock switch that must be depressed or pulled out when the door is opened for the boiler to operate) and observe the operation of the indicator lights on a properly running boiler. Shoot a video or make a chart showing the location of water level control and note whether the light is on or off during proper boiler operations. That way, you will know if a level sensor detects a problem when the boiler fails to fire. Also, most Ignition Controllers will have visible indicator lights, so make the same kind of observations to enable you to troubleshoot water level operations, perhaps saving an expensive, unnecessary service call. Nothing in life is sweeter than fixing something yourself without making it worse.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.