This month’s article concerns the irriguous (great word, look it up) and oft misunderstood subject of treating water for use in boiler operations. Before getting to the heart of the matter, here are a few disclaimers.

- The addition of water with improper chemistry will damage any type of boiler made by any manufacturer.

- In most cases, the damage caused by improper treatment of the water entering your boiler is gradual and cumulative. This slow damage impacts your bottom line in the form of escalating fuel and steam system maintenance costs. Have a look at the accompanying illustration to see just how expensive a thin coating of scale inside your boiler can be.

“Water, water, everywhere, not a drop to drink”. For those who snoozed through high school English Literature class (a class I found eminently snooze), the quote was from Coleridge’s epic poem “Rime of the Ancient Mariner.” My reason for quoting is………. it reminds me of boilers. SAY WHAT? How you might legitimately ask, do I get from a poem about a mariner adrift upon the sea to a boiler? Fair question, and the answer is they’re both about water, which is unusable. More specifically, they’re about water that shouldn’t be used in its current form.

In the mariner’s case, he was adrift on the sea, surrounded by water yet dying of thirst. Yet, he couldn’t just drink the water. He knew the salt dissolved in the water would kill him.

In the case of the boiler, impurities in improperly treated make-up water will likely do the same to your boiler over a period of time. I’ve presented seminars on boilers and other machinery maintenance issues, and invariably, there is someone in the audience who claims that they do not treat makeup water in any way and have had no problems with their boiler. In some cases, it’s true; the reason for it being true is that, fortunately, the quality of the city water where they are located will allow for this non-treatment. However, this is a rare occurrence; water quality varies significantly even in close geographical areas, so beware. Even if the dry cleaner on the next block gets away with it, it doesn’t mean you can.

AND SO WE BEGIN

Water is often referred to as the universal solvent, and therein lies the problem. Water dissolves almost anything that comes in contact with it. Salts, sugars, acids, bases, many gasses, it just doesn’t care; it just dissolves and dissolves and keeps on rolling along.

Take a moment and think about it. What barbarian amongst us would confuse a glass of sparkling San Pellegrino or Perrier with a glass of common tap water? After all, it’s just H2O, isn’t it? Well, the difference in taste is what’s dissolved in the water, and the minerals and gasses that are dissolved in the water are the reason new water being added to the boiler must be treated in order to remove or control the concentration of most of these impurities.

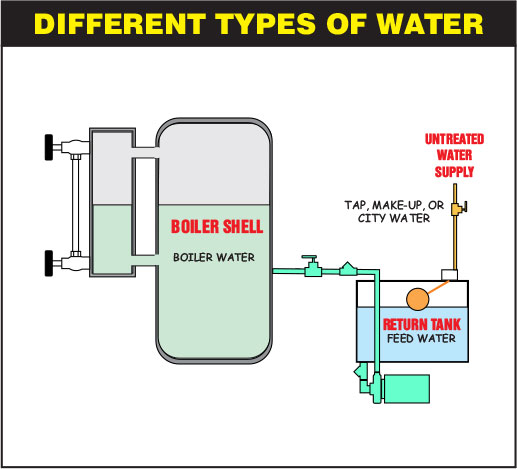

There are three sources of water referred to in this and future articles on this subject:

- TAP, MAKEUP, OR CITY WATER—These terms are used to label the new, untreated water required to replace water consumed during the production of steam. It contains most of the impurities that require treatment.

- FEED WATER—This is the water contained in the return tank. It is a combination of fresh makeup water added to the tank and condensate returning to the return (condensate) tank from the plant machinery.

- BOILER WATER- this is the water contained inside the boiler itself, which will be converted to steam.

From this point forward, we will only be concerned with feed and boiler water. The maximum allowable quantities of dissolved impurities for both feed and boiler water vary slightly with each boiler manufacturer.

Although there is a long list of impurities to be found in water entering the boiler, major ones affecting the operation of boilers found in the dry cleaning and laundry industry are dissolved solids (known as TDS, or total solids) and oxygen, which is dissolved in the new water entering the return tank. This oxygen combines with carbon dioxide to form carbonic acid, a destroyer of the metal in the boiler and piping throughout the steam/return systems.

This is a good place to break for this article, it will be concluded next month when we will delve into what’s actually dissolved in the water and how to treat the raw water rendering it usable in the boiler.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.