CAUTION!

NEVER ATTEMPT TO OBTAIN SAMPLES FROM A BOILER UNDER PRESSURE!

OBTAINING A WATER SAMPLE

Plan on obtaining a water sample when starting up in the morning before the boiler is pressurized. Here’s what you’re going to need:

- A cup or wide-necked beaker to collect the water sample.

- Eye protection if the boiler is hot.

- A pair of leather gloves if there is a chance the decanted water is hot.

An easy way to accomplish the sampling for the boiler water is to use a small ball valve located at the lower end of the sight glass fixture as the boiler is beginning to heat up. Allow some water to flow through the valve to flush any impurities before taking the sample (If there is not a ball valve in the lower sight glass fixture It is advisable to install one). There should also be a valve installed somewhere on the return tank to enable sampling from the return tank. Collect about an inch of water in a clean cup or another wide-mouthed beaker.

USING THE METERS

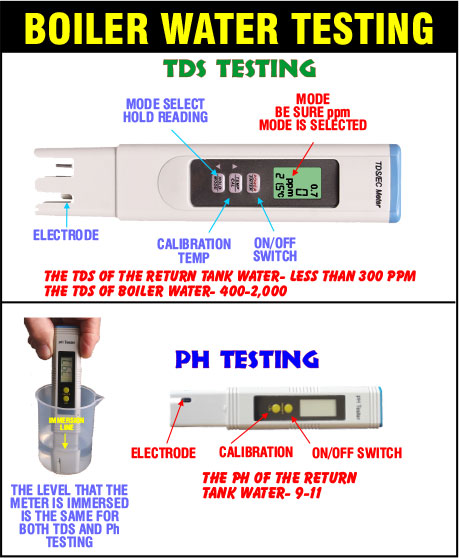

The meters required are for measuring TDS and Ph. They are inexpensive and easy to use. We can supply a kit containing both of these meters and the collection beaker all enclosed in a protective storage case.

The procedure for using both the meters is similar and as follows:

- REMOVE THE CAP COVERING THE SENSING ELECTRODE.

- RINSE THE ELECTRODE IN DISTILLED WATER.

- TURN ON THE METER BY PRESSING THE ON/OFF SWITCH.

- IF THE TDS METER HAS MULTIPLE SCALES SELECT THE SCALE THAT MEASURES TDS IN PPM.

- IMMERSE METER IN SOLUTION UP TO IMMERSION LINE.

- STIR GENTLY AND WAIT 30 SECONDS UNTIL THE METER STABILIZES.

- WHEN FINISHED RINSE ELECTRODE IN DISTILLED WATER, TURN OFF METER AND REPLACE THE CAP.

EVALUATING RESULTS

Results of testing the water samples will determine what steps need to be taken to bring the water treatment into balance with not only current boiler operations, but eliminate the ill effects of past, improper water treatment. We will be testing both for TDS and Ph values. There are three locations at which water needs to be tested and the scale used to run these tests is the PPM scale on the TDS meter.

Since turning water into steam is a series of events it’s important to run these tests in the order shown as well as applying the remedies in the order suggested.

1. Testing the city water entering the return tank- For this test obtain a sample from any faucet. The reading we are interested in here is the (TDS measured on the PPM scale of the TDS meter). If the test results are greater than 250 ppm, if you do not have a water softener you should get one. The cost of the softener and the chemicals to operate it will be significantly lower than the increased costs of boiler compound, wasted fuel, production downtime required for breakdowns and repairs; all these costs are incurred correcting problems caused by hard water. If you’re already using a softener, check its operation and salt level. If those are OK then increase its regeneration frequency.

2. Feedwater in the return tank- Find a convenient fitting to withdraw water from the return tank and measure the TDS value((TDS measured on the PPM scale of the TDS meter). The reading should be less than 300 ppm. If the reading is high check your water softener. If it’s OK, then look for a leaky ball float valve (a very common problem that often goes unnoticed) and/or the check valves between the return pump and boiler water inlet that may be leaking. Run a test of the Ph value, it should be between 9-11, if it is lower you’re in the acidic range which will lead to metal corrosion in the boiler and throughout your steam and return systems. Look for a leaky ball float valve or lack of boiler compound entering the return tank.

3. Boiler Water- Take a sample of the water from inside the boiler. First, test for TDS. If the reading is above 2,000 and the previous tests were OK, it indicates the blowdown procedure needs to be adjusted and/or the amount of boiler compound being used requires adjustment. The easiest solution to try is extending the blow downtimes in 50% increments. Wait 2 weeks and see if there is any change. If not increase the volume of boiler compound by 20% wait 2 weeks and see if that changes anything. If not, try adding another daily blowdown and see if that makes a difference. If not, call our office at 702-376-6693. Second, test for Ph value which should be between 9-11. If it’s low, try increasing the volume of boiler compound by 15% wait 2 weeks, and see if there’s a difference. If not, call our office at 702-376-6693.

The rule of thumb is (provided there are no mechanical problems with the boiler and return system) if the TDS reading is high increase blowdown time, number of daily blowdowns, and/or the volume of boiler compound. If the Ph value is low increase the volume of boiler compound and check the operation of the ball float valve.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.