The next series of articles will be devoted to the safe use of meters in preventing and troubleshooting common problems encountered in the operation of your plant. Included will be the different tests and measurements required, why they are necessary, how to take them, and the meaning of the results. Don’t be concerned about being familiar with terms used in this article, they will be defined and explained as the need arises. Also, for those of you who are hesitant to tackle electrical testing, I’ll be showing you how to safely use these devices.

The list of meters which this series of articles will cover are as follows:

- VOLT/OHM/AMMETER- General electrical testing.

- DIGITAL LASER THERMOMETER- Boiler valve performance checks.

- PH and TDS METERS- Boiler chemistry testing.

LOTS OF DIFFERENT METERS WHICH ONE TO BUY?

The first type of meter in this series is used for general electrical testing and is usually a multimeter. A multimeter has the capability of running many different tests using a single meter. The price of meters is usually dependent on accuracy, repeatability, ease of use, and ruggedness. Requirements for plant troubleshooting are within the range of a multitude of these inexpensive multimeters available priced under $100. The first time you find and fix a problem using them, you’ll have paid for the investment.

This is a list of convenient features a meter should have and what they do:

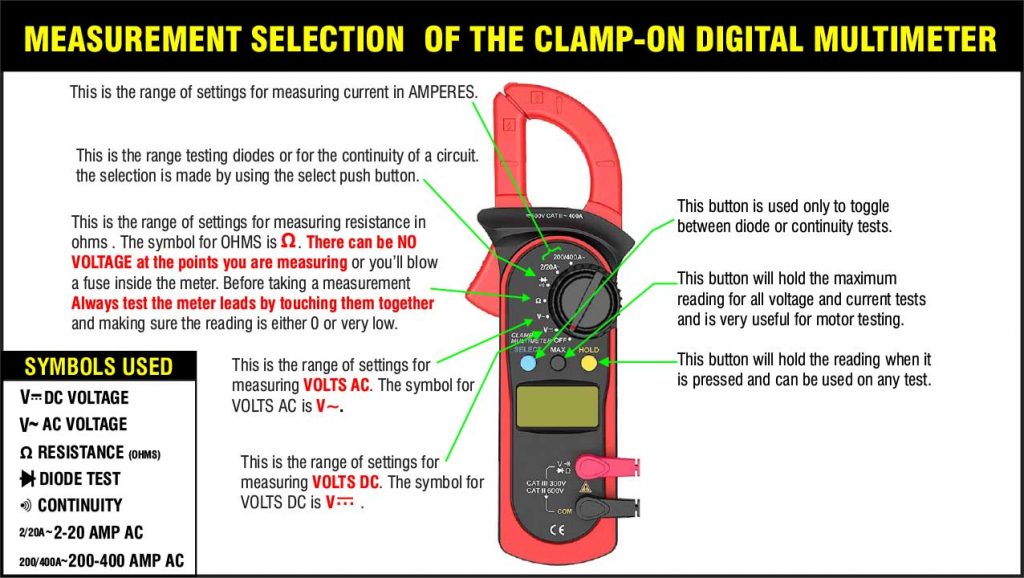

1. METER TYPE- Every meter will have a selection of different measuring capabilities. The three most important for our purposes are voltage, amperes, and resistance. Secondary measurements such as frequency, capacitor and transistor checks, temperature, diode testing, etc. are rarely required at the level of troubleshooting you will be encountering in a dry cleaning or laundry plant. Therefore, there is no reason to spend money on a meter that has features that you’ll never use. With these parameters in mind, my choice is the versatile clamp-on volt/ohm/ammeter. The reason for this choice is the ability for this type of meter to non-invasively measure AC current without interrupting the wiring of the circuit under test.

2. AUTO SHUT OFF (SLEEP MODE)- There are few things more aggravating than to attempt using a meter than discovering you had not turned it off after the previous use and the battery is dead. This is avoidable if you select a meter with auto shut-off. These meters shut down automatically after several minutes when there is no change in the reading.

3. PEAK OR MAXIMUM HOLD- When engaged at the start of a test this feature automatically captures the maximum reading of voltage or current throughout the present test. This feature is vital for troubleshooting motors.

4. HOLD- Similar to the PEAK OR MAXIMUM HOLD selection but it retains whatever the meter is reading when the button is pressed.

5. AUDIBLE CONTINUITY FUNCTION- When testing fuses or tracing wires it’s handy having this feature that will buzz when there is continuity (low resistance) so you needn’t be watching the meter for the result of the test.

6. BACKLIGHTING- This feature illuminates the background of the LCD meter screen for better visibility in poorly lit conditions. Although this feature is handy to have, don’t spend extra money or sacrifice any of the preceding features to obtain the backlighting.

There are a few more inexpensive auxiliary items that are very handy to have when using the meter.

1. CARRYING CASE- Meters are after all a precision measuring device and must be kept clean and dry as well as having a place to store auxiliary leads, clips, batteries, etc. A rigid carrying case or a rugged zip-lock plastic bag is the solution.

2. EXTRA LEADS- Extra leads that can be plugged in and used as extensions as well as adapting to alligator clips and insulation piercing devices.

3. ATTACHMENT AND PIERCING DEVICES- These tools provide access to the wiring on the devices under test.

EXTRA BATTERIES AND FUSES- Hopefully, you won’t be using this meter frequently so rather than going to use the meter and finding a dead battery or blown fuse is frustrating. Keeping these items in the case with your meter case is a good idea.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.