The disaster for this month will be the failure of the water pump. This pump forces a liquid “coolant” through the coils of the condensers to remove the heat from these condensers. In water tower installations, the pump is either located on the roof near the water tower, or on the floor near the dry cleaning machine, and the coolant is water. In a chiller, the pump is generally inside the enclosure housing the refrigeration components, and the coolant is either water or a mixture of water and anti-freeze called “brine”.

Before we get into managing this species of disaster, here are a few words about prevention. These pumps seldom fail without giving ample warning of an evolving problem. If the circuit breaker in the electrical panel that controls the pump trips frequently, it is a sure sign of looming disaster. IF YOU ARE NOT EXPERIENCED IN WORKING WITH ELECTRICITY, HIRE AN ELECTRICIAN FOR THE FOLLOWING PROCEDURES.

Be sure to set the breaker for the pump in the off position, remove the protective electrical plate at the rear of the pump, then take a good look at the wire connections at the pump with the aid of a flashlight. There is little room for the wire connections at the end of the pump, and pumps vibrate, causing the screw connections or push-on connectors to loosen and eventually fail; this is the problem area in many cases.

Observe if there is any melted insulation, bluing, or discoloration of the wires or connectors; if so, replace them.

Remove the cover to the appropriate breaker panel and switch off the breaker controlling the pump. Make sure the screws holding the wires in place are securely tightened down. Using a flashlight, observe if there is any melted insulation, bluing, or discoloration of the wires or circuit breaker connections or the area where the circuit breaker attaches to the power busses in the breaker box.

Another harbinger of doom is frequent pump motor shut down due to the motor’s internal protective thermostat. If this is the case, follow the same steps outlined in the previous paragraph, and in addition, MAKE SURE THE LOUVERS THAT ALLOW AIR TO FLOW THROUGH THE MOTOR ARE FREE OF LINT, DUST, OR OBSTRUCTIONS. You can drastically shorten the time this internal thermostat requires to reset by obtaining a bag of ice, placing it inside another strong plastic bag, and laying it on the far end of the pump motor. Remember, this is only a temporary solution.

The following goes for all equipment. DO NOT USE THE CIRCUIT BREAKERS AS SWITCHES TO TURN EQUIPMENT ON AND OFF! This practice degrades the breaker’s performance and sometimes keeps the breaker from tripping at the correct current levels. Each machine should have a disconnect close by; use this for switching instead of the breaker.

Another pump killer is excessive head pressure. Several factors could cause this and will be indicated by a high reading (45 PSI and above) on the pump outlet pressure gauge if you have one installed.

Also, the pump’s starting-up sound will differ under high head pressure. Trying to describe sounds is nearly impossible, but the best way I can is to say that when starting the pump, the sound will take longer to even out (sorry, best I could do). Causes of this problem often lie in the bypass valve being shut or not sufficiently opened or the clogging of strainers going into the dry cleaning machinery.

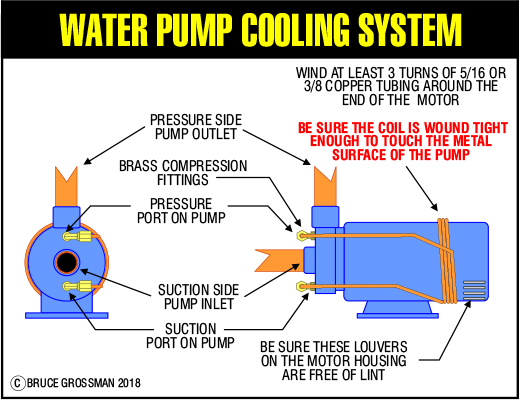

Whether you’re currently having problems with your circulating pump or not, installing a cooling coil to prevent the pump motor from overheating would be a good idea. The illustration accompanying this article shows an easy and inexpensive installation.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.