We all know how rising energy and supply costs continue to gnaw away at the bottom line. Controlling these costs has never been more vital to a successful operation. Yet, many maintain the same outmoded attitude towards waste as when solvent, filter cartridges, natural gas, etc., cost a fraction of what they do today. Leaking steam traps are one of the biggest culprits contributing to fuel wasted in producing steam.

STEAM TRAPS, THEY’RE EVERYWHERE

Firing your boiler and distributing the steam throughout your plant is a significant operating expense, and it can also be the most wasteful. A component In that steam distribution system is a neglected device called a steam trap. Steam traps are simple and remarkably durable; however, they can cost you a small fortune when faulty! Steam traps are not passive devices. Like any machine, traps have moving parts that will eventually fail. According to the US Department of Energy, “In steam systems that have not been maintained (meaning checked for faulty traps) for 3 to 5 years, between 15% to 30% of the installed steam traps may have failed.”

The average package plant without shirt equipment has between 15 and 20 traps. Add another 10 traps for shirt equipment, and you’ve got 25 to 30 traps. Do the arithmetic; in the best-case scenario, there are at least 2-4 faulty traps (depending on the size of your plant). The annual cost is at least $700 per faulty trap, which wastes thousands of dollars each year in unnecessary energy consumption due to this easily rectified maintenance problem.

The following is a list of the most common symptoms of failed steam traps:

TRAP STUCK SHUT

- When a trap is stuck shut or partially clogged, the problem is simple to diagnose. The equipment associated with a faulty trap will either not heat up or will heat up very slowly and not maintain heat. When live steam is used (buck or head steam, puff irons or hand irons, spotting boards), large quantities of water and/or very wet steam will be discharged.

TRAP STUCK OPEN

- A heavy and continuous plume of white steam shooting from your return tank (generally, this is seen on the plant roof) indicates a trap or traps stuck open failure. Ordinarily, when traps operate correctly, you will see puffs of almost transparent steam coming from the return tank vent.

- The return tank will be extremely hot, and the boiler feed (return) pump may run continuously and cannot push feed water into the boiler. This overheating is possibly caused by trap stuck open failure (this situation could also indicate other boiler problems such as faulty check valves).

- Equipment sensitive to steam pressure, like stills unable to reach operating pressure, yet the trap is hot. You will notice this by very slow distillation. One possible cause is a trap open failure

- A spike in fuel costs that is not proportional to increased production.

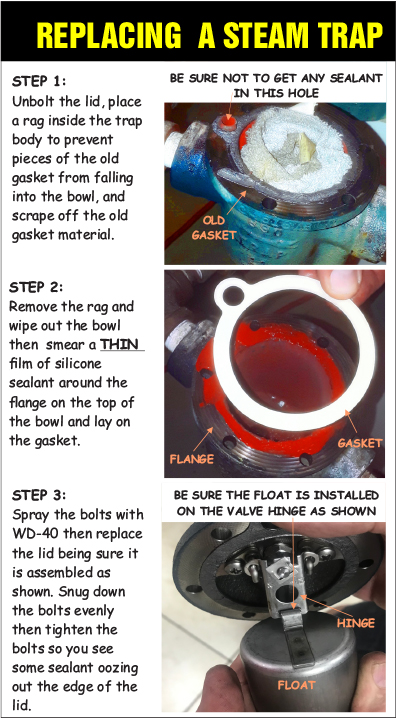

So what can be done for faulty traps and the resulting waste of energy? I’ve found the most effective method of dealing with faulty traps is simply going through the plant and replacing them. You’re likely thinking, “what a nightmare to replumb all those old pipes.” Well, that’s unnecessary. In most cases, all that must be done is to remove and replace the trap’s lid, which contains all the faulty parts. Unfortunately, you will need to purchase a complete new trap from the same manufacturer as the one you are retrofitting, and remove the lid to replace the old one. I recommend this rather than just replacing the parts on the old lid. See the accompanying photos for instructions. Use a paint pen to write the date of the swap out on the newly replaced lid.

Bruce Grossman

Bruce Grossman is the Chief of R&D for EZtimers Manufacturing. EZtimers is the manufacturer of the new EZ DOSE boiler compound manager and return tank level control which replaces that troublesome ball float valve in the condensate return tank and automatically adds the correct amount of boiler compound to the return tank preventing the oxygen corrosion and scaling. Our SAHARA and DIB-M high purity separator water mister/evaporators provide a thrifty, legal method to get rid of the separator water generated by your dry-cleaning machine. See our Ad in this issue and for further information on EZtimers products visit www.eztimers.com Please address any questions or comments for Bruce to bruce@eztimers.com or call 702-376-6693.